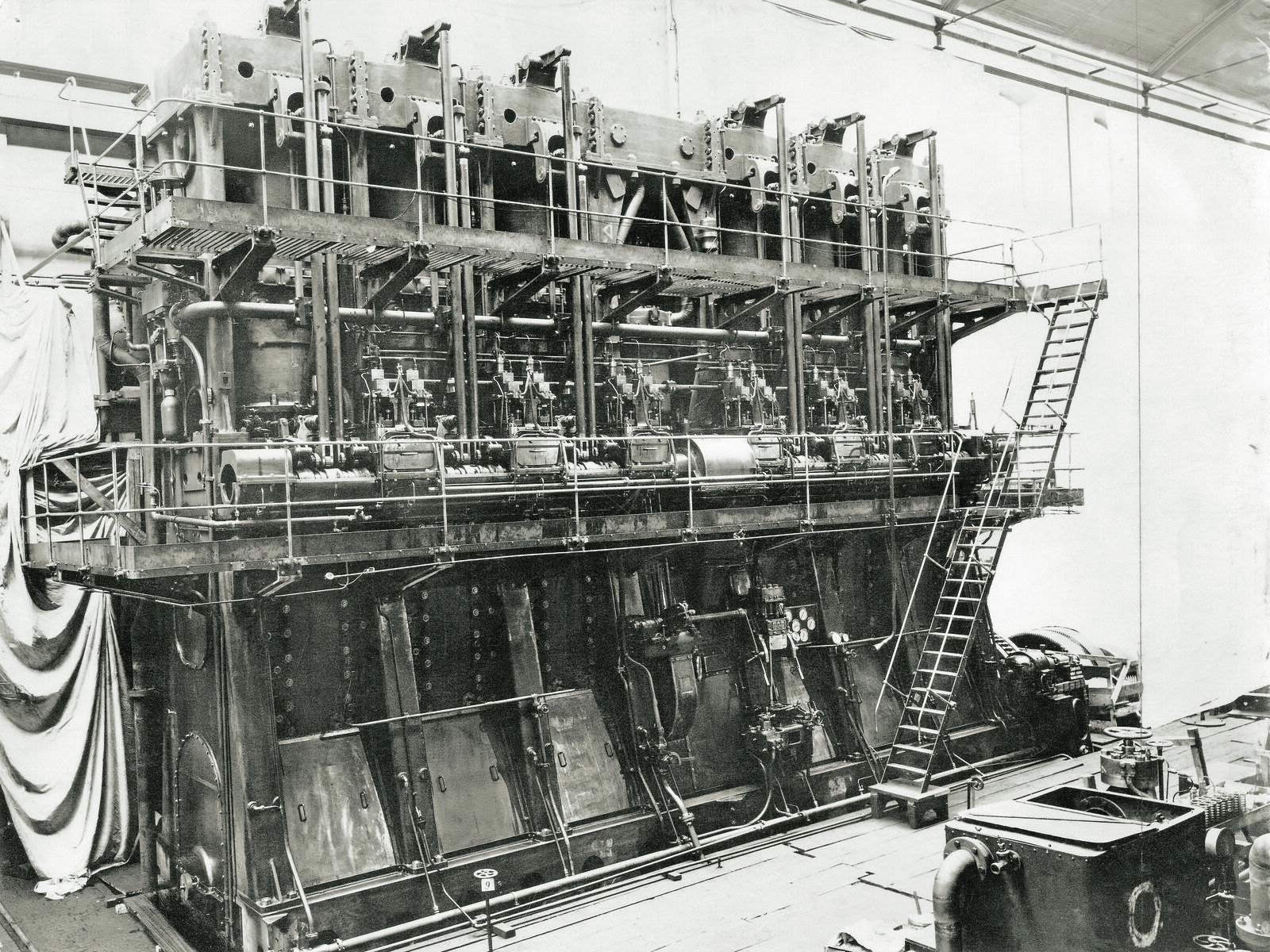

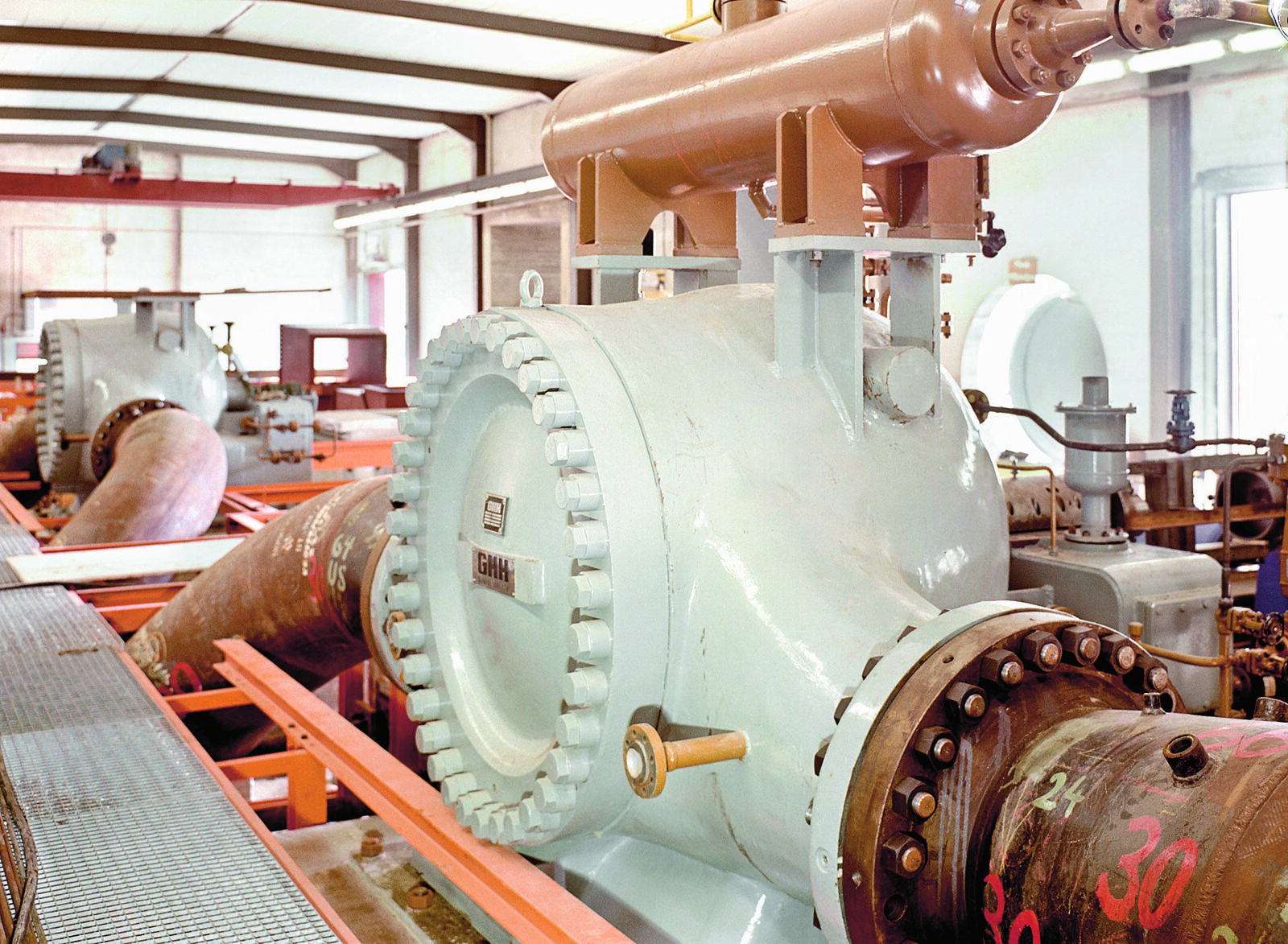

The three-letter MAN name originates from its former name “Maschinenfabrik Augsburg-Nürnberg”. Today the MAN Group comprises four large business units. The largest of them is MAN Truck & Bus, based in Munich. In 2012 its truck and bus products and transport solutions generated 15.7 billion euro, representing 55.1 percent of the MAN Group’s total sales. Sales of large diesel engines and turbo machines by the MAN Diesel & Turbo unit accounted for 23.9 percent of the total. MAN Latin America consolidates all the Group’s commercial vehicle operations in Central and South America, and generated 18.1 percent of total Group sales in 2012. Renk AG, in which MAN SE holds a 76 percent share, generated 2.9 percent of total sales with its heavy-duty gear systems.

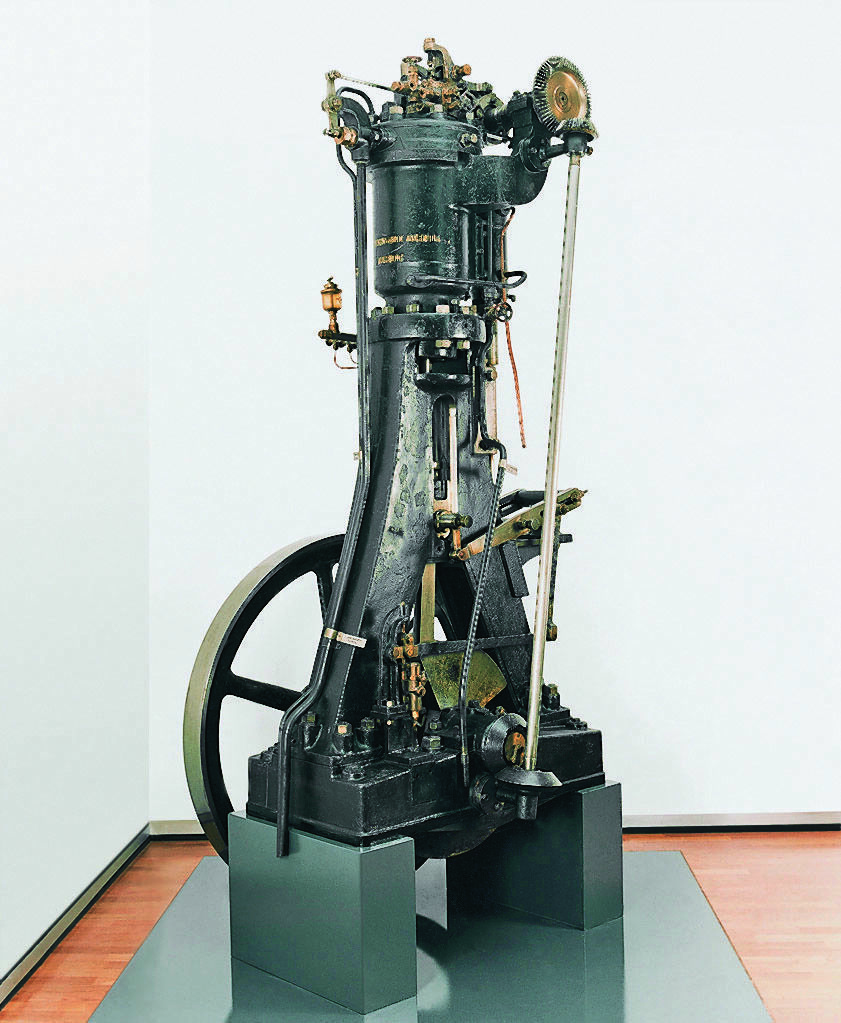

Most of the MAN Group’s sales are generated by the production and sale of diesel engines and commercial vehicles. Efficient drive and energy systems are the core brand values to which MAN has adhered throughout its more than 250- year history. It was the invention of the diesel engine, with its wide-ranging application variants, along with the continual development of ever more economical engines which enabled the MAN brand to establish itself and prosper. That long and illustrious history was reason enough for the company to mark its 250th anniversary in 2008 not only by looking back to the beginnings of the business in the 18th century, but also by celebrating two of its major milestones: the development of the diesel engine by Rudolf Diesel at the Maschinenfabrik Augsburg, including his design of the first prototype to run under its own power on August 10, 1893; and the manufacture of the first truck featuring direct diesel fuel injection in 1923.

The name MAN was actually only first introduced in 1986, following the merger of M.A.N. AG into the Gutehoffnungshütte Aktienverein mining and engineering corporation to create the newly named MAN Aktiengesellschaft – eliminating the three dots of the abbreviation. The history of the brand, with its numerous innovations, changes of ownership, acquisitions and disposals, and its move from mining, iron and steel into engineering and the manufacture of commercial vehicles, is a history of specialisation and continual change.