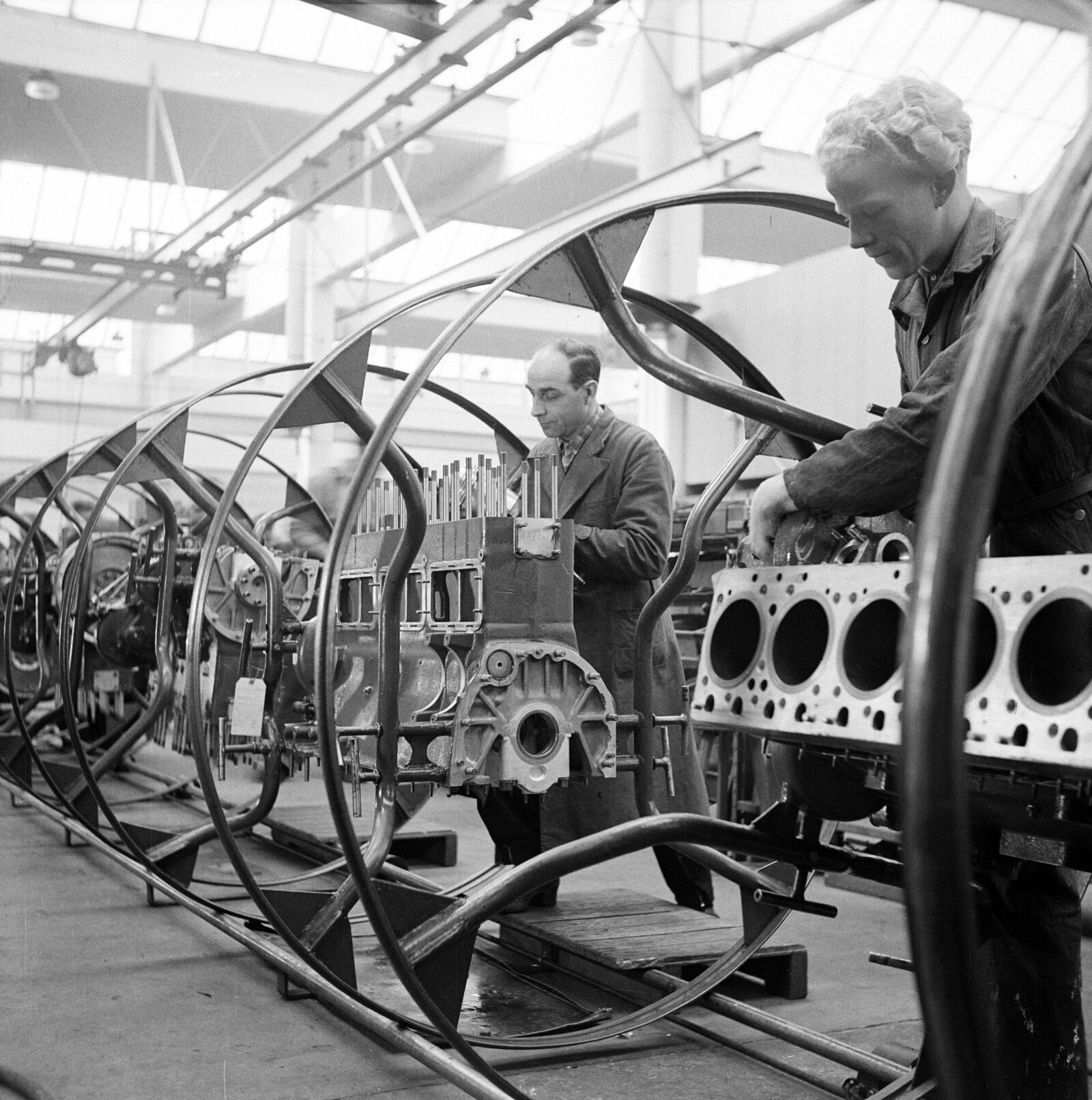

The company’s turbo engines provided it with its key competitive edge. “More power, fewer revs” was the designers’ watchword in attempts to achieve higher efficiency while at the same time cutting fuel consumption and emissions and reducing running noise. Competition with Volvo boosted the pace of research and development progress, which culminated in the 350 horsepower V8 turbo-diesel launched in 1969 – the most powerful truck engine on the European market at the time. Another key area of Scania-Vabis’s development focus was on constructional design improvements, and in 1968 the company launched a new generation of front-wheel drive trucks

The tipping cab was more spacious and easier to get into, and the truck’s handling was improved.

Having merged with Saab to form Saab-Scania AB in 1969, from 1972 until the two companies parted ways in 1995 Scania was run as an independent business unit of the Group’s Automotive division. The first decade under the new corporate umbrella was marked by international growth and the development of a modular product range. Factory capacities in the Netherlands and Brazil were expanded. In early 1976, Scania opened a facility in Tucumán in northern Argentina to make gearboxes, among other products. Brazil was Scania’s biggest selling market in 1977. From 1979 to 1981, the brand sold as many as 4,000 vehicles a year in Iraq. By 1979, exports accounted for almost 90 percent of total sales.

Scania launched its new truck range in 1980. Not just the engines, gearboxes and axles, but also the frames and cabs, had been developed as a modular system. For the trucks weighing between 16 and 36 tonnes there were three engines, three classes of chassis and four cab models, enabling them to be tailored exactly to customers’ transport needs. The attractive design came from Giorgio Giugiaro, and was complemented by outstanding ergonomic qualities which set ground-breaking new standards in terms of safety and comfort for the driver. Scania’s customisable range of trucks was complemented by special maintenance programmes, developed jointly with its f leet customers, which helped avoid off-the-road times due to breakdowns.

The modular concept speeded up new developments and reduced manufacturing costs. Additionally, Scania’s “Series 2” provided just the right response to the transport industry’s rising demands in terms of the vehicles’ operational reliability and economy. More cost savings for customers were brought by the turbo-compound engine launched in 1991, which utilised the energy in the exhaust gases by way of a “power-recovery turbine”. This boosted power while cutting fuel consumption, which was reduced even further by the aerodynamic Streamline cabs. With its new generation of trucks, Scania increased vehicle sales between 1980 and 1989 from 26,566 to 35,602 units, including 3,884 buses and coaches.

The modular component kit system is still today the foundation stone of the company’s success. Scania established the second key precondition for increasing profitability and growth during the 1990s by building up a global production system of specialised and logistically interlinked plants. Scania focused its European component production primarily in Sweden: Cab production was relocated from Meppel in the Netherlands to Oskarshamn, while engine and axle production – including the research and development function – was moved from Zwolle to Södertälje and Falun. In return, Dutch subsidiary Scania Nederland B.V. expanded the capacity of the Zwolle plant. It has been the central location for final assembly of trucks since 1989. As labour-intensive body assembly was hampering economies of scale, in 1991/92 a new assembly plant was built at Angers in France. Scania subsequently restructured its production facilities in Latin America based on the same model. The restructuring provided major growth momentum. Sales increased during the 1990s from around 35,000 vehicles to 50,000. Having parted from Saab in 1995 and been renamed Scania AB, the company was listed on the Stockholm Stock Market in 1996.