“As part of Volkswagen Group’s investment planning, the Board of Management and Supervisory Board today set the cornerstones for securing the Group’s future success. The transformation of the Group and its brands and the strategic focus on the core areas of mobility will be consistently implemented. Considering the enormous challenges we face in the coming years, our financial basis is very solid,” said Hans Dieter Pötsch, Chairman of the Supervisory Board of the Volkswagen Group.

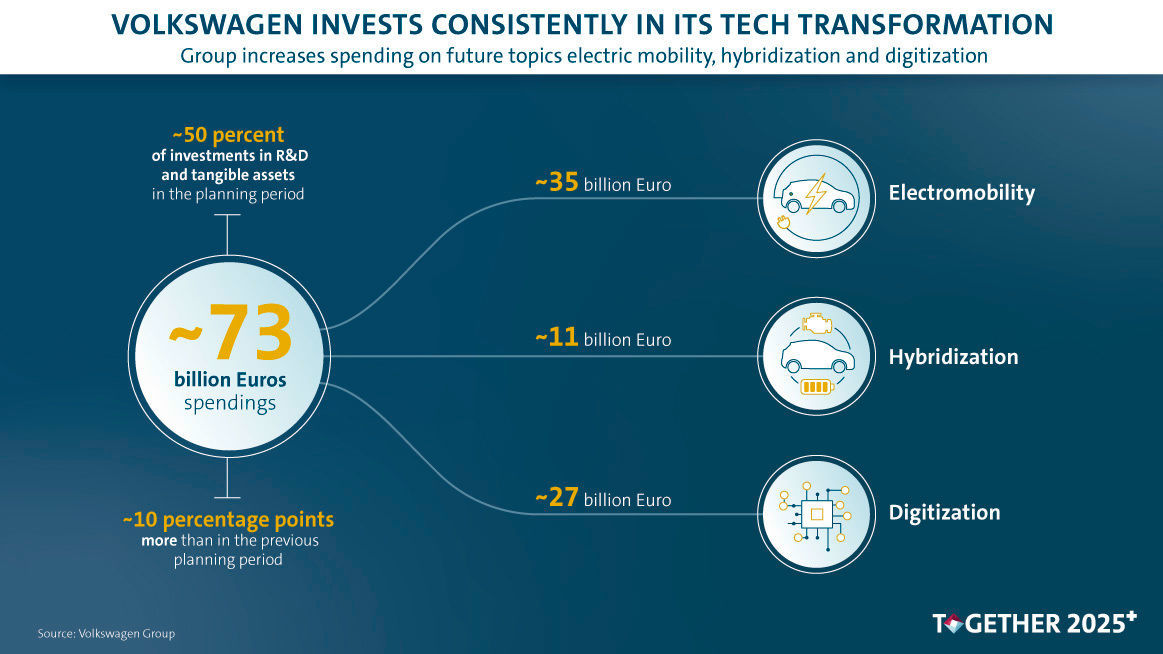

“Having set the course for a battery-electric future in the Volkswagen Group early on, we are now a global leader with our electric platforms and a broad range of electric vehicles,” said Herbert Diess, Chief Executive Officer of the Volkswagen Group. “In the coming years, it will be crucial to also reach a leading position in car software in order to meet people’s needs for individual, sustainable and fully connected mobility in the future. To that end, we have doubled our digitalization spend.”

Bernd Osterloh, Chairman of the General Works Council, commented: “The investments demonstrate that our Group walks the talk when it comes to transformation, electric mobility and digitalization. We will go fully on the offensive in the coming years. Yet, just as important as billion-euro budgets are a common understanding of the transformation and adequate planning reliability. This is where all of us – employees, managers, the Board of Management and also policy-makers – come in. As regards the latter, I am thinking in particular of Berlin and Brussels and hot topics such as charging infrastructure and high-speed Internet. Volkswagen is fully committed to climate-friendly, highly networked mobility. But for this, we and our customers need a reliable environment.”

The Planning Round is based on the expectation that the global economy will grow moderately over the next five years. Moderate growth with regional differences is also anticipated for the individual markets. The increase in productivity of 30 percent and savings in administration are to secure the transformation financially. In addition, the Group is systematically working on the optimization of its product portfolio. Thus, model variants, engine-transmission combinations and features that are less in demand will be streamlined in order to reduce the complexity and increase the efficiency of the portfolio. The planning excludes the joint venture companies in China, since they are not part of the consolidated group and finance investments in plants and products from their own resources.

Electric mobility and hybrid technologies

Volkswagen was the first automaker to commit to the Paris Agreement and aims to become climate neutral by 2050. Over the next ten years, the Group intends to launch approximately 70 all-electric models by 2030. Around 20 of these are already in production, with 50 more to follow. In addition, around 60 hybrids are planned by the end of the decade, slightly over half of which are already being manufactured.

The Planning Round envisages production of approximately 26 million fully electric cars by 2030. Some 19 million of these vehicles will be based on the Modular Electric Drive Toolkit (MEB), with most of the remaining seven million to use the high-performance PPE platform. The Group estimates production of around seven million hybrid vehicles over the same period.

Significantly greater emphasis on the key topic of digitalization

Due to the crucial role that software will play for Volkswagen’s future success, capital spending on digitalization will total around EUR 27 billion, double the amount set in the previous Planning Round. This includes spending on the Group’s Car.Software organization, which was successfully launched earlier this year. The goal is to build a proprietary software stack, which will be deployed in Audi’s Artemis project from 2024. The company's own share in software is to increase from 10 to 60 percent. In addition, a large share of the funds earmarked for digitalization will be invested in the mission-critical fields of artificial intelligence, autonomous driving and digitalization of significant business processes.

Transformation of Germany as a center of industry to be pushed

By investing in its German sites, Volkswagen, as one of the country’s largest industrial players, is contributing to a strong German economy,while continuing to push the country’s transformation into a more sustainable and more digital future with long-term job security. After Saxony, Lower Saxony will become Germany’s second center of electric mobility.

In Salzgitter, the Group will invest around one billion euros in the strategically important battery technology. In conjunction with its Swedish joint venture partner Northvolt, Volkswagen will build a cell production facility there that will start operation in 2024 and increase the competitiveness of Germany as an industrial location. This is a further key element in the successful transformation of the Volkswagen Group Components division, initiated back in 2015.

At the individual locations, the strategy of consolidating product families at multi-brand plants will be continued in order to leverage even more synergies between the brands and achieve further efficiency gains.

Wolfsburg will add a model to its portfolio: another SUV targeting the European market will roll off the assembly line from 2024. The site already produces the entire Golf family with all its derivatives, the Volkswagen Tiguan and the SEAT Tarraco.

In future, Volkswagen Commercial Vehicles will build the all-electric ID. BUZZ at its Hanover location, along with three fully electric D-SUV models for other Group brands. The Hanover site is thus accelerating the transformation to electric mobility that has already commenced.

At the Volkswagen’s brand plant in Emden, the transformation is also progressing rapidly: while the construction work for the switch to electric mobility is fully on track, the second electric model for the site has now been defined. In addition to the ID.4, the four-door all-electric Volkswagen Aero is scheduled to be manufactured there from 2023.

At the same time, the Passat currently built in Emden will be produced in Bratislava, Slovakia, starting in 2023 – together with the ŠKODA SUPERB family – which will leverage synergies within the vehicle family here, too. Moving production of the SUPERB from the Czech plant in Kvasiny to Bratislava will give ŠKODA the necessary capacity in the Czech Republic to carry out the brand’s growth plan.